GETTING STARTED

. What else does AMECO offer beside Roll Forming?

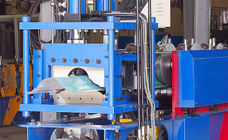

We manufacture roll-forming and metal processing machinery which perform roll forming, stamping, punching, bending, fold forming, and shearing sheet metal.

Well crafted professional products are designed and manufactured such as roll forming machines, curving forming machines, folding forming machines, press-brake machines, hydraulic shearing machines, cut to length lines, slitting lines, coil coating lines, and coil galvanization lines.

. Do you do custom roll forming machinery or custom coil processing equipment?

Yes, we do. We specialize in designing and manufacturing custom machine. Just providing us your desired profiles and requirements such as component brand, type of material, we can make machines that fit your needs.

. How many models of machine do you make?

We have three models for Roll Forming with three different prices: Advance, Standard, and Eco.

. How fast is your machine?

Speed depends on machine’s type: 4-9M/min for Tile Roofing Roll Forming Machine; 20M-38M/min for Roofing Roll Forming Machine; up to 60M/min with fly shearing for high speed Corrugated Roofing Roll Forming Machine.

. Does AMECO hold any certifications?

ISO 9001

. Do you offer on-site visits?

Yes, we do. We visit your site for installation, training, repairing and other purposes as required.

. Can you ship internationally?

Yes, we can. We have shipped machines to all over the world - 32 countries across 5 continents.

. What methods of payment do you accept?

We accept the following forms of payment: L/C, T/T, and Cash

TECHNICAL QUESTIONS

. What material thicknesses can be roll formed?

We process steel strip with a thickness of 0.12 – 0.8mm .

. Can your machine process full hard material?

Yes, it can. Material Strength: G300 – G550

. Can one machine produce many profiles?

Yes, it can. E.g.: Double Layer Roll Forming Machine can produce two roofing types; C purlin can be adjusted to produce up to 12 profiles.

. Can you assist us at making a machine that matches our current machine?

Yes, we can. Please give us detailed information; we will evaluate its suitability for the current roll forming process and offer suggestions to maximize production efficiency.

. Can you bend the edges of the sheet to each side?

Yes, we can.

. Do you make “Text logo embossing” (logo stamp-press)?

Yes, we do.

. How many years/ in which condition does your machine last?

Our customers have been using Ameco machines over 10 years until now (with suitable maintenance).

. How many containers does one roll forming line need?

One roll forming machine line needs 1 cont. 40HC or 1 cont. 40 HC & 1 cont. 20 DC or 2 cont. 40HC depends on your order.

VISIT AMECO in VIETNAM

. How far is AMECO Office from Tan Son Nhat airport?

About 5 minutes by car.

. How far is AMECO factory from Tan Son Nhat airport?

About 1 hour and 15 minutes by car

. How can I visit a roll forming line?

Please tell us in advance so that we can arrange a Factory Tour and pick you up. Contact: [email protected] or +84988731731.

AFTER-SALES SERVICE

. Warranty?

AMECO is willing to repair defects and make exchanges against malfunctions due to manufacturing defects for 12 months from the loading date. Repairs will be made free of charge.

. Repair Service Arrangement?

Please contact AMECO Customer Service at +8498873171 or [email protected] to inform about AMECO machines’ issues. We will arrange technician(s) to support you online (with simple cases) or come to your factory to fix them.

. For how long my machine will be checked/ repaired?

We try to fix your machines as fast as possible. Maximum is two days from notification date; our technicians will start taking care of your machines.